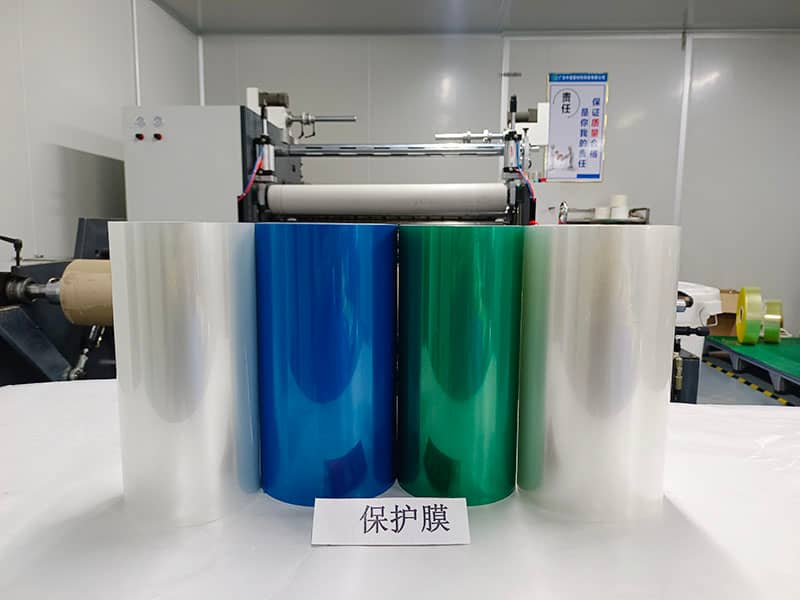

General non-residual protective film

Product Features

.The product is made of PET, PP, and other materials, with a PSA coating.

.Good cleanliness and flatness

.We provide customized protective film solutions tailored to clients’ specific application requirements and technical specifications, including various types of protective films based on acrylic, silicone, and PU adhesive systems, with customizable thickness, peel strength, and color options.

Product use

The product is suitable for online die-cutting, waste discharge, and protective manufacturing/shipping solutions for products such as mobile phones, computers, and touch panels.

Protective film made from mobile ph- one

Screen Protector

Product mix

|

Typical product property indicat- ors |

|

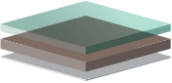

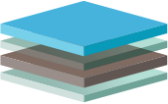

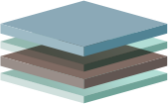

Substrate layer, Backing layer, Adhesive layer, Release liner |

|||||

| Product model | Collateral sys- tem | Substrate type | Substrate thickness (μm) | Aggregate thickness μm | 剥离力 (stripping force) = gf/inch | Pigment | |

| SDKT0382H | Acroleic acid PET 38 44 3~6 | Transpar- ent | |||||

| TR-5001-LLLP | Acroleic acid PET 50 58 0.1~3 | Transpar- ent | |||||

| SDKT0502H | Acroleic acid PET 50 58 3~6 | Transpar- ent | |||||

| SDKT0703H | Acroleic acid PET 70 78 6~ 12 | Transpar- ent | |||||

| TR-1001-L | Acroleic acid PET 90 105 6~ 12 | Transpar- ent | |||||

| TR-7501-L | Acroleic acid PET 70 85 6~ 12 | Transparent / Blue | |||||

| TR-5001-CPH2P | Acroleic acid CPP 50 72 60~ 100 | Transpar- ent | |||||

| TR-7501-CPHP | Acroleic acid CPP 75 90 30~60 | Transpar- ent | |||||

| SDK3209 | Acroleic acid CPP 50 65 30-60 | Transpar- ent | |||||

| SDK2291C | Organic silicon PET 50 60 0.1~3 | Transpar- ent | |||||

| SDK2392 | Organic silicon PET 70 80 3~6 | Transparent / Blue / Red | |||||

| SDK2292 | Organic silicon PET 50 60 3~6 | Transparent / Blue / Red | |||||

| SDK2493 | Organic silicon PET 90 100 6~ 12 | Transpar- ent | |||||

| SDK2K92SF | Organic silicon PET 36 46 3~6 | Transpar- ent | |||||

| SDK2191X2 | Organic silicon PET 23 51 4.4~7.6 / 740~ 1060 | Transpar- ent | |||||

| SDK2291T | Polyurethane PET 50 65 <3 | Transpar- ent | |||||

| SDK2281T | Polyurethane PET 50 60 <3 | Transpar- ent | |||||

02 WANSEN – Protective Film Series

Anti-static protective film

Product Featu- res

.It has excellent anti-static ability

.The coating in the thousand-grade clean room has stable bonding strength and weather resistance.

.The thickness and bonding strength can be customized according to the customer’s specific application requirements.

.The anti-static pattern layer allows customers to customize selections based on their specific usage scenarios.

Product Use

Process and shipment protection for TN/STN/TFT polarizers, optical films, and display products

Product mix

| Typical product property indicat- ors |

|

←

← ← ← |

Antistatic layer; Antistatic agent layer; Polyester film layer; PET film Acrylic adhesive Release film |

||||||||

| Product model | Collateral sys- tem | Substrate type | Thickness μm | Shear force gf/ inch | Glaze impeda- nce value Ω/sq | Membrane sur-

face impedance value Ω/sq |

Separation

voltage KV |

Pigment | Special perform- ance | ||

| TR-1001-H4P-E4P | Acroleic acid | PET 115 100~200 / 4~8 / | Transpar- ent | Membrane

resistance |

|||||||

| SDK2282 | Acroleic acid | PET 60 3~6 9-11 / <500 | Transpar- ent | Gelatinous ant- iseptic | |||||||

| SDK2284L-E9-J | Acroleic acid | PET 69 ≤6 ≤9 ≤9 <500 | Transpar- ent | Bimodular ant- ibody | |||||||

| SDK2395B-TP | Organic sili- con | PET 85 20~25 / 6~9 / | Blue | Membrane

resistance |

|||||||

| SDK2392-DE | Organic sili- con | PET 85 3~6 9~ 11 6~9 <500 | Transparent / Blue | Bistatic | |||||||

| SDK2291FX-D3 | Organic sili- con | PET 58 1-4 / 6-9 / | Transpar- ent | Membrane

resistance |

|||||||

| TR-7501-LLLG Blue-DE | Organic sili- con | PET 85 1~3.5 9-11 6-9 <500 | Blue | Bimodular ant- ibody | |||||||

| SDK2K91X3 Blue | Organic sili- con | PET 84 1~3 / <9 / | Blue | Membrane

resistance |

|||||||

| SDK2291S 1-2 | Organic sili- con | PET 60 1-3 / / / | Transpar- ent | / | |||||||

| SDK2282T | Polyurethane | PET 60 3~6 8-11 / <500 | Transpar- ent | Gelatinous ant- iseptic | |||||||

Functional Coating Protective Film

Product Featu- res

. The AR (Anti-Reflection) protective film features high light transmittance (>94%) and low reflectivity (<2%), offering superior performance.

. The AG (Anti-Glare) protective film effectively reduces glare, enhances viewing angles, and minimizes eye strain.

. The HC (Hard-Coating) protective film features a surface hardness of up to 3H on a pencil scale, delivering exceptional scratch resistance.

. A blue light protection film, specially treated with BLC technology, effectively blocks blue light in the 380nm-500nm wavelength range.

. Printable protective film with excellent surface printability

. Stable Adhesion and Good Adherence

Product Use

Scratch-resistant protective film is applied to display panel surfaces (e.g., glass, acrylic), CRTs, mobile phones, and touch screens to prevent scratches during use. Printing-ready protective film ensures secure shipping by protecting products during die-cutting and coding processes.

Protective film made from mobile ph- one Screen Protector

Product mix

|

Typical functional coating |

|

|

Functional coating; PET film substrate; PET backing |

|||||||||

| Product model | Structure | Thickness μm | Transmittance% @550nm | Fog level % | Pencil hardness | Remarks | ||||||

| SDK50T-HC-AR PET+HC+AR 53 94.5 1.4 H | Reflectivity <2% | |||||||||||

| SDK50T-AG(SMT) PET+AG 54 90.5 35 H | / | |||||||||||

| SDK50T-AS-E PET+HC 53 90.5 0.52 H | Surface impedance ≤e 9 | |||||||||||

| SDK188T-AR-C PET+UV hard coating 193 ≥90 ≤2 2H | Haqi test: internal

fogging within 5 seconds |

|||||||||||

|

Functional Coating Protective Film (Coating Matching Adhesive System) |

||||||||||||

| Product model | Collateral sys- tem | Substrate type | Aggregate thickness μ

m |

Skin Leaving force gf/inch | Pigment | Hardness | ||||||

| SDK2295F | organic silicon | PET | 60 | 20~30 | Transpar- ent | / | ||||||

| SDKZ291 | organic silicon | PET | 65 | 0.1~3 | Transpar- ent | / | ||||||

| SDK2291HC-EB | organic silicon | PET | 63 | 1~5 | Transpar- ent | H | ||||||

| SDK2491HC-EB | organic silicon | PET | 135 | 1~5 | Transpar- ent | H | ||||||

| SDK2596A-HC | organic silicon | PET | 172 | 30~50 | Transpar- ent | 3H(500g) | ||||||

| SDK50T-HC-4S | organic silicon | PET | 53 | / | Transpar- ent | 2H | ||||||

High Temperature Resistant Protective Film

Product Features

.Low shrinkage PET substrate

.Demonstrates excellent high-temperature resistance (150℃ -220℃) without residual adhesive after exposure to high temperatures.

.It offers stable bonding strength and weather resistance, with thickness and bonding strength adjustable according to customer requirements.

. The PET shrinkage ratio (MD/TD) can be customized according to the customer’s specific application scenarios.

Product Use

For high-temperature resistant process protection, such as ink printing protection in mobile phone/PDA cover manufacturing, PVD processes, or ITO thin film process protection.

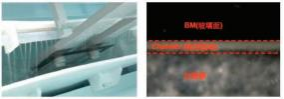

Protecting the ink printing on the cover of mobile phone

Product mix

| Typical product property indicat- ors |

|

|

Low-shrinkage polyester film; Acrylic adh- esive

Release liner |

|||||||||

| Product model | Collagen sy- stem | Substrate type | Thickness μm | Shear force gf/inch | Thermostability ℃ | MD contraction percen- tage | TD contraction percen- tage | Pigment | ||||

| SDK27K01J | polyurethane | PET | 15 | 3-8 | 180 | |||||||

| SDK2201G | acroleic acid | PET | 60 | 1~3 | 150 | 0.2% | 0. 1% | Transpar- ent | ||||

| SDK2202G | acroleic acid | PET | 60 | 3~6 | 150 | 0.2% | 0. 1% | Transpar- ent | ||||

|

High temperature resi- stance test |

||||||||||||

After the protective film was attached to the glass and baked at 150℃ for 2 hours, no residue remained on the glass.

| General protective film | SDK2202G | |||

| 0.5 hour | 1 hour | 2 hour 0.5 hours under the micr- oscope to confirm the residual glue | 1 hour | 2 hour |

Acid-resistant Protective Film

Product Features

.The protective film has the function of resisting hydrofluoric acid .Excellent bonding stability and peelability, no residual adhesive .The adhesive is compatible with ITO and non-corrosive.

Product Use

For acid-resistant process protection, such as in the secondary reinforcement process of touch panel OGS

Product Mix

PO film

PET substrate; PET film

Acrylic adhesive; Release liner

specifica- tions

| Name of a part | PET substrate thickness (μm)

Standard wide |

PO substrate thickness (μm) | Tape thickness: μm | Adhesive fo- rce

980mm |

High frequency resis- tance | ||||||||

| Standard meter | 200m | ||||||||||||

| SDK2507C-1 | 90 | 100 | 230 ± 10 | SUS: 50±10 gf/inch | ≤20% | ||||||||

| GLASS: 55±10 gf/inch | |||||||||||||

| SDK2544HF | 90 | 100 | 245 ± 10 | SUS: 50±15 gf/inch | ≤20% | ||||||||

| GLASS: 55±15 gf/inch | |||||||||||||

| SDK2404C | 90 | / | 115 ± 5 | SUS: 25±10 gf/inch | ≤20% | ||||||||

| GLASS: 30±10 gf/inch | |||||||||||||

| SDK2405C | 90 | / | 110 ± 5 | SUS: 20±10 gf/inch | ≤20% | ||||||||

| GLASS: 20±10 gf/inch | |||||||||||||

| Typical product property indicat-ors | |||||||||||||

| Product model | Collagen sy- stem | Substrate type | Substrate | thickness (μm) | Aggregate thickness m | μ | Strength to hydrofluoric acid | Pigment | |||||

| SDK7720 | acroleic acid | PVC | 190 200 | <20% | Transparent / Blue | ||||||||

Hydrofluoric Acid Resistance Test of SDK2507

Attach the double-sided surface of SDK2507C to the glass and immerse it in 20% hydrofluoric acid at room temperature for 30 minutes. Tests confirmed no corrosion residue on the CG and SG surfaces.

Recyclable Protective Film

Product Features

.Eco-friendly products made with special EVA adhesive and recyclable BOPP substrate, meeting modern environmental standards for material recycling.

Product Use

Suitable for various conventional protective film applications, including process protection and finished product protection.

Protective case for mobile phone assembly

Product mix

|

|

← BOPP/PE

← Primer ← EVA |

|||||

| Typical product property indicat- | |||||||

| ors | |||||||

| Product model | Collagen sy- stem | Substrate type | Thickness μm | Viscosity (N/cm) | Pigment | ||

| SDK E20 EVA PE 55 0.08 | Transpar- ent | ||||||

| SDK 27K02Y-J3 EVA BOPP 60 0.2 | Transpar- ent | ||||||

| SDK E50 EVA PE 75 0.2 | Transpar- ent | ||||||

| SDK 27K02T EVA BOPP 85 0.2 | Transpar- ent | ||||||

WANSEN Protective Film Bilingual Document (English-Arabic)

| English |

| WANSEN Protective Film: Premium Protection for Global Applications |

| WANSEN protective film series delivers versatile, high-performance solutions tailored to global standards, ideal for European, American and Middle Eastern markets. |

| Crafted with top-tier materials like PET, PP, and recyclable BOPP, our films integrate advanced adhesive systems (acrylic, silicone, PU) and functional coatings (anti-static, AR, AG, HC) to meet diverse industry needs. |

| Key strengths include customizable thickness, peel strength, and color options, paired with exceptional durability—high-temperature resistance (150℃-220℃), acid resistance (hydrofluoric acid compatible), and anti-static performance—ensuring reliable protection during processing, shipping, and use. |

| Eco-friendly recyclable options align with European and American sustainability values, while robust weather resistance and stable bonding suit the Middle East’s harsh environmental conditions. |

| Suitable for mobile phones, computers, display panels, polarizers, and touch screens, our films prioritize cleanliness, scratch resistance (up to 3H pencil hardness), and residue-free adhesion. |

| From general non-residual films to specialized anti-static, high-temperature, and blue light-blocking variants, WANSEN offers tailored protection that balances quality, functionality, and global compliance. |